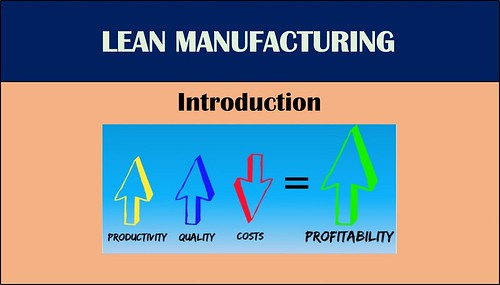

Lean manufacturing is a production procedure based upon an ideological background of increasing performance while concurrently minimising waste within a manufacturing procedure. The lean concept sees waste is anything that doesn’t include value that the consumers want to pay for.The benefits of lean manufacturing consist of lowered preparations and also operating costs as well as boosted item quality.Also referred to as lean manufacturing, the methodology is based on a specific manufacturing principles that have actually influenced manufacturing systems throughout the world along with those of various other markets consisting of health care, software application and also numerous service industries.The core concept in executing lean manufacturing is to get rid of waste to continuously improve a process. By decreasing waste to provide procedure improvements, lean manufacturing sustainably provides value to the customer. The kinds of waste include procedures, tasks, services or products that require time, money or skills however do not create worth for the consumer. These can cover underused skill, excess stocks or inefficient or ineffective processes as well as procedures.Removing these ineffectiveness need to improve solutions, minimize expenses and ultimately provide cost savings for a specific service or product with the supply chain to the customer.Waste in industry, whether that is still employees, inadequate procedures or unused materials are a drain on performance, and also lean manufacturing aims to get rid of these. The motives behind this vary relying on viewpoint, from boosting earnings to supplying benefits to consumers. Whatever the over-arching motives, there are 4 key advantages to lean manufacture: Eliminate Waste, Improve Quality, Reducing Costs, Reducing Time.

The five core concepts of lean manufacturing are defined as value, the value stream, circulation, draw as well as excellence. These are currently used as the basis to carry out Japanese lean terms. They are, Value: Value is figured out from the point of view of the customer and also associates with just how much they agree to spend for services or products. This value is then produced by the producer or provider who must seek to eliminate waste and also costs to satisfy the ideal rate for the customer while also increasing profits.Map the Value Stream: This concept includes evaluating the products and various other sources called for to create a product or service with the objective of determining waste and renovations. The value stream covers the whole lifecycle of an item, from basic materials to disposal. Each phase of the production cycle requires to be analyzed for waste and also anything that doesn’t add worth must be gotten rid of. Chain placement is typically advised as a means to accomplish this step.Modern manufacturing streams are usually intricate, needing the cooperations of designers, scientists, designers as well as even more, with the real manufacturing of a physical item being just one part of a wider stream of work.Create Flow: Creating circulation is about getting rid of useful barriers to improve preparations. This ensures that processes flow efficiently as well as can be embarked on with marginal hold-up or other waste. Disrupted as well as disharmonious production processes sustain prices as well as creating flow suggests ensuring a continuous stream for the production or service delivery.Establish a Pull System: A pull system functions by just commencing job when there is need. This is the opposite of push systems, which are made use of in manufacturing source planning (MRP) systems. Press systems establish inventories in advance with production readied to meet these sales or manufacturing projections. Due to the error of numerous forecasts, this can result in either also much or not sufficient of a product being produced to meet need. This can cause extra warehousing prices, interrupted schedules or bad client fulfillment. A pull system just acts when there is need and relies on flexibility, communication and efficient procedures to be successfully achieved.The pull system can entail teams only moving onto new jobs as the previous actions have actually been finished, permitting the group to adapt to obstacles as they occur in the understanding that the previous work is mostly still relevant to providing the product or service.Perfection: The pursuit of perfection using ongoing process enhancements is likewise known as ‘Kaizen’ as created by Japanese Motor Corporation owner. Lean manufacturing needs recurring analysis as well as enhancement of procedures and procedures to continuously eliminate waste in an effort to locate the excellent system for the value stream. To make a meaningful and long-term difference, the concept of continuous renovation must be incorporated through the society of an organisation as well as requires the dimension of metrics such as lead-times, production cycles, throughput and also cumulative flow.

It is very important for the society of constant renovation to filter through all degrees of an organisation, from staff member as well as task supervisors right as much as the exec level, to create a collective obligation for enhancement and also value creation.Lean manufacturing brings numerous benefits and also negative aspects depending upon exactly how and also where it is implemented.The advantages of lean are Saves Time and Money, Environmentally Friendly, Improved Customer Satisfaction.Lean manufacturing is a method that can aid streamline as well as boost manufacturing processes or various other solutions in order to provide enhanced advantages for customers, while conserving time and money through the elimination of waste.As a technique, lean is best applied throughout the whole of an organisation with constant surveillance as well as renovations being used with the support of employees at all degrees.